With the continuous improvement of the efficiency of the Flatbed semi-trailer now and the rapid development of the modern highway. The industry has paid attention to semi-trailers. They have gradually become the main vehicle for long-distance logistics. The trailer’s braking system is crucial to driving safety. It can shorten braking distance and improve safety. This helps avoid major accidents. This is of great significance to improve the safety of the transport industry.

Table of Contents

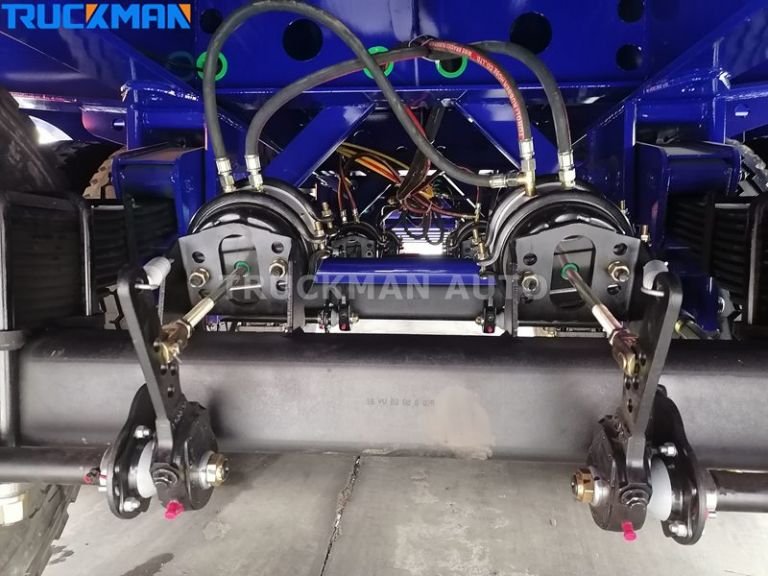

The Importance Of Flatbed Semi Trailer Braking System

A locomotive flatbed trailer braking system is one of the key pieces of equipment to ensure safety. It can effectively control the speed of the locomotive so that the locomotive can smoothly decelerate or stop when needed. In an emergency, the performance of the braking system is directly related to the safety of passengers and cargo. A good braking system can reduce the risk of accidents and improve the operating efficiency of locomotives. Also, technology has led to the braking system integrating new functions. These include energy recovery. It helps to improve energy use and cut pollution. Old braking systems can’t meet the requirements. This is especially true for the long braking distance at high speeds and the gradual loss of braking force during continuous braking. We can address these challenges by improving the design of the braking system. We can also better the wear and heat resistance of brake materials. Lastly, we can add advanced electronic control technologies, to further improve the performance and reliability of the braking system. At the same time, the influence of different types of suspension systems on the braking system is very important to ensure optimum performance under all conditions.

Development Of Flatbed Trailer Braking Technology

The advent of the ABS braking system in the 1930s was undoubtedly a milestone. Before this, most semi-trailers relied on mechanical braking, which was not only inefficient but also a major safety hazard. ABS and EBS braking systems improved braking a lot. They also greatly enhanced road safety. The ABS pair has many advantages. But, there are still problems. These include wear on the friction lining and slow response in the conventional braking system. To improve the braking performance of trucks, EBS based on anti-lock brake ABS and anti-skid brake ASR has also been developed.

EBS’s full name is Electronically Controlled Brake System (EBS). It has standard system components and is highly integrated. This cuts production and installation costs and boosts vehicle economy. Most importantly, EBS is a big tech innovation for vehicle brakes. It is characterized by:

- Electronic activation of all braking system components;

- Reduction gears and engine brakes are integrated into the service brake application;

- Braking force distribution adapted to load distribution;

- Braking consistency between tractor and trailer is achieved;

- With comfortable deceleration control;

- Continuous self-testing through integrated diagnostic and monitoring functions.

Types Of Advanced Braking Systems

The main types of advanced braking systems include disc brakes. They also include anti-lock braking systems (ABS) and electronic stability control (ESC). Here are their benefits:

Disc brake: Disc brakes exhibit good stability when exposed to heat. This is mainly because disc brakes have no self-energising force. So, their braking is largely unaffected by the coefficient of friction. Disc brakes have superior heat dissipation. This is mainly due to their larger brake discs. They provide a wider area for heat to dissipate, which makes heat dissipate faster. This avoids the problem of high brake temperatures. Disc brakes have a smaller gap between the brake pad and the disc, which ensures a faster braking response.

Anti-lock braking systems: ABS prevents wheel lock and slip during braking by regulating brake line pressure. It can improve the car’s stability when braking. It can also improve its maneuverability when braking and reduce local tire wear.

ECS: It has a shorter brake response time and pressure build-up time. This fixes the problems of mechanical brake response time and poor brake comfort. It has better brake management. It can meet the braking needs of both truck heads and semi-trailers. EBS can control the brake parts as the vehicle moves. The system has built-in ASR to avoid vehicle side slips and fix ABS defects. The Flatbed trailer can also be retrofitted with Vehicle Stability Control ESC on an EBS basis, Automatic Cruise Control ACC, and the new Vehicle Stability Assist function in the future.

Benefits Of Advanced Braking Systems

The advantages of a high-tech braking system are mainly reflected in the following aspects:

High safety: The high-tech braking system can analyze road conditions and vehicle speed. It can use that data to adjust braking force and stopping distance. This makes for a more stable and reliable braking effect. This is crucial to improving driving safety.

Energy saving and environmental protection: The high-tech braking system can adjust the braking force. It does this according to the vehicle’s speed and the driver’s pedal pressure. This system reduces false braking and hard braking. It also saves energy and protects the environment through technologies such as energy recovery.

High control performance: The high-tech braking system can control the brake parts precisely. This makes the vehicle’s braking smoother. In emergency braking, high-tech brakes can respond faster. They improve the vehicle’s handling.

Strong adaptability: High-tech braking systems can recognize road conditions. They can respond to them, resulting in better braking.

Advanced Brake System Challenges and Solutions

Challenges: First, most drivers have a biased, subjective understanding. They think only the tire holds dead. But, there are clear tire drag marks on the road. They show the strongest braking force. Second, the ABS on Flatbed trailers performs worse than on imported semi-trailers. It is less effective at braking in tough transport conditions. ABS on Flatbed trailers often fails to skid. This is because it does not get maintenance and repair.

Solutions: Increased publicity on the benefits of advanced braking systems:

Put more effort into publicizing the benefits of advanced braking systems. This will help drivers, owners, and operators of semi-trailer trains fully understand that these systems have these advantages:

- Reduce excessive tire wear and reduce running costs;

- It can improve directional maneuvering during braking and prevent head pushing;

- It can better keep the vehicle stable during emergency braking. It prevents skidding and tailgating.

- An advanced braking system improves braking efficiency. It can make the wheels do the best braking while rolling or dragging.

- In the rain and snow or during emergency braking, a flatbed semi trailer with an advanced braking system will handle better.

- Advanced braking systems can alleviate the phenomenon of brake heat recession. For example, mountain roads have long, steep slopes, many bends, and sharp curves. Drivers use the brake often. This causes brake heat damage. It leads to loss of control, which causes one-car accidents.

Summary

An advanced braking system is very important for the safety of flatbed semi-trailers. The advanced braking system can shorten the braking distance and improve the braking performance of the vehicle. When braking, the pressure can be adjusted to avoid wheel locking. This keeps the vehicle in the best braking condition. It can also prevent the wheels from clasping, thus reducing the possibility of losing control of the vehicle and improving the stability of the vehicle. It can adapt to different road conditions, including wet and muddy roads. This improves the vehicle’s braking on these roads. Prioritize safety when choosing a braking system for your vehicle. Use well-known components, such as WABCO.

FAQ

It can improve the side-to-side stability of vehicle braking. It can also improve the maneuverability of vehicle braking. And it can reduce excessive local tire wear. The benefits of transporting with a flatbed trailer go beyond the improved braking system to include the many advantages that come with its overall design and functionality.

The system brakes well. It can analyze road conditions and vehicle speed. Then, it can adjust the braking force and stopping distance. This leads to a more stable and reliable braking effect.

The main factor is good braking. Also, good stability when braking, smooth braking, and the brand of brake accessories.

According to GB7258-2017.7.2.12, all semi-trailers with a gross mass greater than 3,500kg shall be equipped with a compliant anti-lock braking device. Trucks that carry dangerous goods and have a gross mass of 12,000 kg or more must also have an electric brake system (EBS).